Description

1. Overview

Black plastic concrete formwork is a revolutionary construction material in the field of concrete casting. It is fabricated from high-quality engineering plastics, typically through advanced molding techniques. The distinct black color is often due to the addition of specific pigments or additives during the manufacturing process, which also contribute to its enhanced performance properties.

2. Material Characteristics

- High Strength and Durability: Engineered to withstand significant pressure from freshly poured concrete. It can resist deformation, ensuring that the final concrete structure maintains accurate dimensions. This durability means it can be reused multiple times across different construction projects, providing excellent cost-effectiveness in the long run.

- Water Resistance: The plastic material forms a seamless, waterproof barrier. This prevents water absorption, which is crucial as any moisture penetration into the formwork could weaken its structure over time and also affect the quality of the concrete surface by causing uneven drying or water stains.

- Smooth Surface Finish: The inner surface of the black plastic formwork is extremely smooth. When the concrete cures against it, this smoothness transfers to the concrete, resulting in a high-quality, blemish-free finish that often requires minimal post-casting finishing work, such as sanding or plastering.

3. Thermal Properties

Black plastic formwork has unique thermal properties. The black color, being a good absorber of heat, can accelerate the initial curing process of concrete, especially in sunny or warm environments. This can potentially shorten the overall construction cycle, allowing for faster project completion. At the same time, it also provides some insulation, helping to maintain a more even temperature within the concrete mass, which reduces the risk of thermal cracking.

4. Installation and Handling

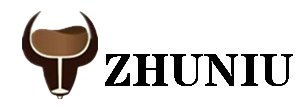

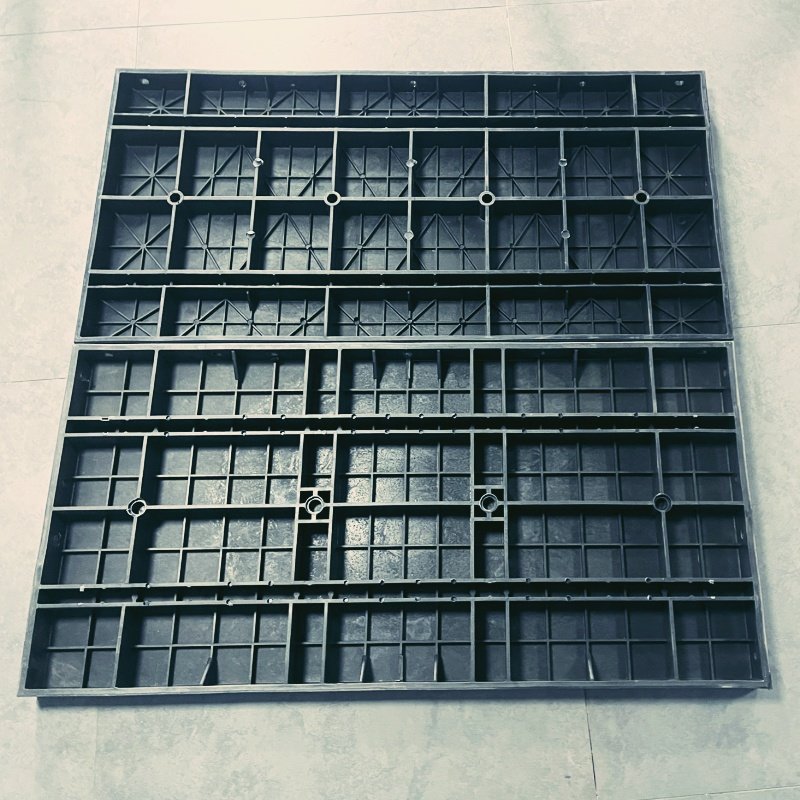

- Lightweight and Maneuverable: Compared to traditional wooden or metal formworks, black plastic formwork is much lighter. Construction workers can easily carry, assemble, and disassemble it, which not only improves on-site work efficiency but also reduces the need for heavy machinery in some cases.

- Modular Design: Most black plastic formwork systems come in modular units. These can be quickly snapped together or detached, enabling flexible configuration to fit various project requirements, whether it’s for building foundations, columns, or wall structures.

5. Environmental Advantages

- Recyclability: Being made of plastic, it is highly recyclable at the end of its service life. This aligns with modern sustainable construction practices, reducing the environmental impact associated with construction waste.

- Reduced Deforestation: As an alternative to wooden formwork, its widespread use helps to conserve forests, minimizing the demand for timber resources in the construction industry.

6. Cost Considerations

- Initial Investment: While the upfront cost of black plastic formwork may be slightly higher than some low-quality, disposable formwork options, its reusability quickly offsets this expense. Over multiple projects, the cost per use drops significantly, making it a more economical choice for contractors looking at long-term cost savings.

- Maintenance Costs: It requires minimal maintenance. There is no need for painting, treating against rot (unlike wood), or rust prevention (unlike metal), further adding to its overall cost-efficiency.

7. Price

Click to leave your contact information, Please feel assured that we will give you the best discount.