Description

H20 Beam Plywood timber – Beam Introduction

Structure and Design

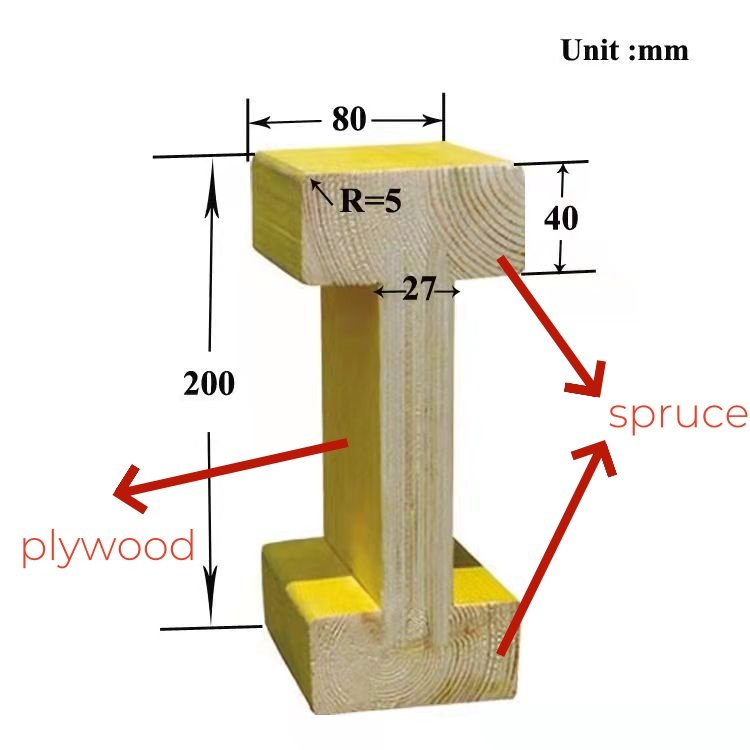

- It features a unique I – shaped cross – section. The flange components on the top and bottom provide excellent load – bearing capabilities. These flanges are usually made of high – quality laminated veneer lumber (LVL), which ensures strength and stability. The web in the middle, often a plywood material, connects the two flanges firmly, creating an integrated and robust structure.

- The H20 dimension indicates its depth, typically around 20 centimeters (the actual dimension may vary slightly depending on the specific manufacturing standards), allowing it to span reasonable distances without excessive deflection.

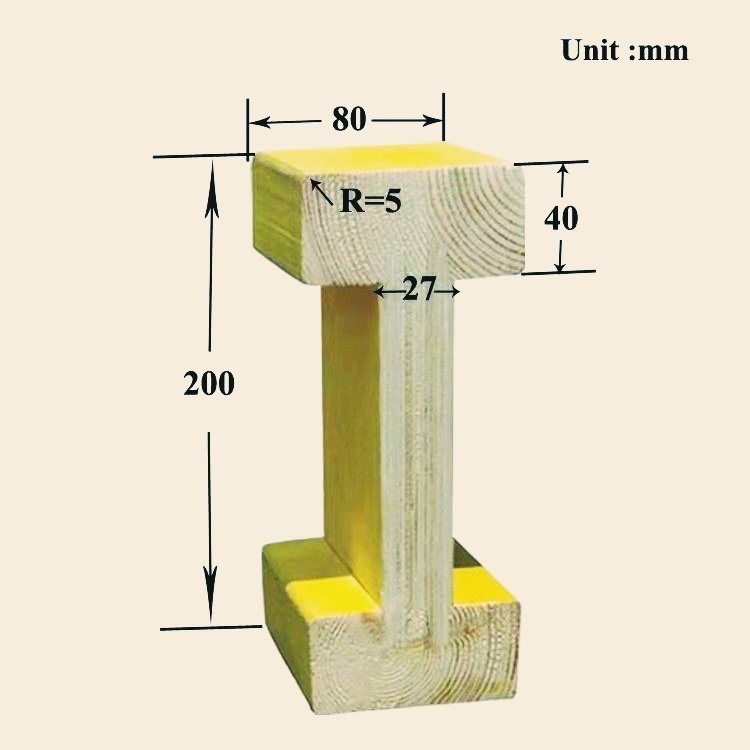

Product Detail:

H20 beam dimensions

H20 beams are composed of spruce wood on both flanges and a web made of multi-layer structural boards, with stress eliminated through finger joint technology to ensure overall rigidity and stability.

What is the weight in kg/m of Zhuniu H20 beam?

H20 beams weighs approximately 4.8 kg per meter, with its surface painted with yellow waterproof paint.

Both ends can be covered with red plastic protective caps or metal caps.

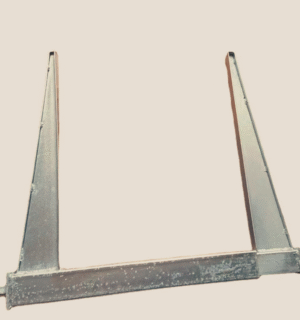

Red Plastic Protective Caps Metal Protective Caps

length

H20 Beam Length: 1.8m, 2.9m, 3.0m, 3.3m, 3.9m, 4.9m, 5.9m Other lengths of any size can be customized.

HS code: 4418830090

Advantages

- Strength and Stiffness: The H20 timber beam plywood can support heavy loads, making it suitable for applications such as floor joists and roof rafters. It can effectively distribute the weight of people, furniture, and other loads in a building structure, reducing the risk of structural failure.

- Lightweight: Compared to traditional solid wood beams of the same load – bearing capacity, the H20 wood I – beam is much lighter. This property makes it easier to handle during construction, reducing labor intensity and installation time.

- Dimensional Stability: Thanks to the laminated structure of the flanges and the well – designed combination with the web, the H20 wood I – beam is less likely to warp, twist, or shrink due to changes in humidity and temperature. This stability ensures the long – term performance and integrity of the structure it is used in.

- Versatility: It can be easily cut, drilled, and connected with other building materials such as metal connectors and plywood sheets. This enables builders to customize it according to specific construction requirements and architectural designs.

technical indicators

- bending strength:553kN / m2 【standard:>450】

- shear strength: 25.03kN 【standard:>23.9】

- bearing capacity: 49.91kN 【standard:>47.8】

- bending moment capacity : 12.08kNm 【standard>10.9】

Applications

- Floor Systems: Widely used as floor joists in residential and commercial buildings. It provides a solid base for floor sheathing and can support the weight of the flooring materials and the live loads on the floor.

- Roof Structures: Serves as roof rafters, helping to support the roof covering and withstand the forces exerted by snow, wind, and other environmental factors.

- Wall Framing: Can also be incorporated into wall structures to provide additional support and stability, especially in situations where there is a need to carry heavy loads through the walls.

Service

We can provide customers with various certification documents related to H20 beams timber plywood, and also offer fumigation services for the products.

Price

Click to leave your contact information, Please feel assured that we will give you the best discount.

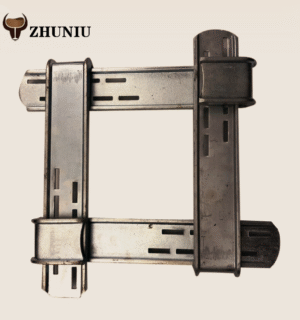

Product Matching

Connection Reinforcer

Construction cases