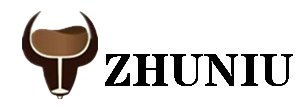

Description

Introduction

Plastic concrete wall formwork is an important construction material and tool widely used in the field of building construction. It plays a crucial role in shaping and forming concrete walls with high precision and efficiency.

Material Characteristics

- Durability: Plastic formwork is usually made from high-quality engineering plastics. It has strong resistance to corrosion, which means it can withstand the erosion of various substances in the construction environment, such as moisture, alkaline substances in concrete, etc. Unlike traditional wooden formwork that may rot or get damaged easily under long-term exposure to damp conditions, plastic formwork can maintain its structural integrity for a relatively long time. For example, in a coastal construction project where the air is highly humid and contains salt, plastic formwork can still perform well without significant deterioration.

- Lightweight: It is much lighter than traditional steel or wooden formwork. This lightweight property makes it easier to handle and transport on the construction site. Workers can carry and install it with less effort, which can improve the construction efficiency. Suppose in a high-rise building construction, when workers need to lift the formwork to upper floors, the lightweight plastic formwork can be easily hoisted by cranes or carried by manpower along staircases.

- Smooth Surface: The inner surface of plastic concrete wall formwork is very smooth. After the concrete is poured and solidified, the formed concrete wall surface will also be smooth, reducing the need for subsequent surface treatment work like plastering to a certain extent. It can directly present a good visual effect and meet the requirements of some decorative concrete wall applications.

Structural Design

- Modular Design: Plastic formwork often adopts a modular design concept. It consists of multiple standard-sized panels that can be easily assembled and disassembled. Builders can combine these panels according to the specific size requirements of the wall to be constructed. For instance, if a wall is 5 meters long and 3 meters high, appropriate numbers of formwork panels of certain widths and heights can be selected and connected together to form the complete formwork structure for that wall.

- Connection System: There are usually special connection components designed for plastic formwork. These connection parts can firmly fix adjacent panels together to ensure that the formwork maintains its shape and stability during the concrete pouring process. Some common connection methods include snap-on connections or the use of bolts and nuts, which make the installation and disassembly operations quick and convenient.

Advantages in Construction

- Reusability: Plastic formwork can be reused multiple times. As long as it is properly maintained after each use, cleaning it and checking for possible damages, it can be applied in many construction projects successively. This not only reduces the consumption of construction materials but also helps to lower the overall construction cost in the long run.

- Fast Construction Speed: Due to its easy assembly and disassembly features and lightweight nature, the construction cycle of concrete walls can be shortened. Workers can complete the installation of the formwork quickly and then start the concrete pouring work in a timely manner. After the concrete hardens, the formwork can also be removed rapidly to carry out the next construction steps.

Application Scenarios

Plastic concrete wall formwork is widely used in various building construction projects, including residential buildings, commercial complexes, industrial plants, and infrastructure projects like bridges and tunnels where concrete walls need to be constructed. It provides a reliable and efficient solution for creating high-quality concrete wall structures.