In the dynamic world of construction, having the right tools and materials is crucial for the success of any project. One such essential item is the plastic round column formwork. This article aims to provide you with a detailed overview of plastic round column formwork available for sale, covering its features, sizes, prices, construction methods, and customer feedback.

Features of Plastic Round Column Formwork

- Lightweight Design: Plastic round column formwork is significantly lighter compared to traditional formwork materials like steel or wood. For instance, a plastic round column formwork panel with a height of 750 mm and a diameter of 300 – 450 mm can be easily carried and maneuvered by construction workers. This not only reduces labor costs but also speeds up the installation process. As an example, in a multi – story building project, workers can quickly transport the plastic formwork to different floors without the need for heavy – duty lifting equipment for each piece.

- Durability: Made from high – quality materials such as polypropylene (PP) reinforced with fiberglass, these formworks are designed to withstand the rigors of construction. They can be reused up to 100 times in some cases. The fiberglass reinforcement adds strength to the PP base, making the formwork resistant to cracks and breakages even after multiple uses. In a long – term construction project that spans several months or years, the durability of plastic round column formwork ensures that it remains a cost – effective choice throughout.

- Smooth Surface Finish: The surface of plastic round column formwork is smooth, which results in a high – quality finish on the concrete columns. Concrete does not stick to the plastic surface, eliminating the need for a release agent in most cases. This smooth finish not only enhances the aesthetic appeal of the columns but also reduces the need for additional finishing work such as plastering or sanding. In a commercial building lobby where exposed concrete columns are part of the design, the smooth finish provided by plastic formwork can showcase the beauty of the concrete structure.

- Easy Assembly: Assembly of plastic round column formwork is a straightforward process. Many models can be assembled by simply rotating the handles or fastening bolts. This simplicity means that less – skilled workers can be trained quickly to carry out the installation, reducing the overall labor time and cost. For example, in a small – scale residential construction project, a team of local workers with basic training can efficiently assemble the plastic round column formwork.

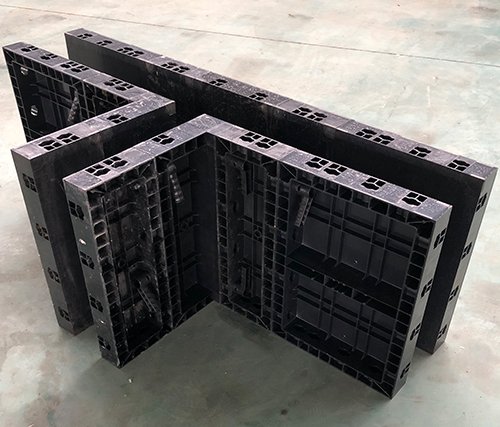

- Stackability: Plastic round column formwork is designed with special stack grooves, allowing for easy stacking during transportation and storage. This not only saves space but also protects the formwork from damage. In a busy construction site with limited storage space, the stackability of these formworks ensures that they can be stored neatly and retrieved easily when needed.

Sizes of Plastic Round Column Formwork

Prices of Plastic Round Column Formwork

Construction Methods Using Plastic Round Column Formwork

- Site Preparation: Before installing the plastic round column formwork, the construction site needs to be prepared. This includes ensuring that the foundation is level and stable. Any debris or obstacles around the column location should be cleared.

- Assembly: The plastic round column formwork is assembled on – site. The panels are brought together, and the connection mechanisms (such as handles or bolts) are used to secure them in place. Workers should ensure that the formwork is properly aligned and tightened to prevent any leaks during concrete pouring.

- Reinforcement Placement: Once the formwork is assembled, steel reinforcement bars are placed inside the formwork according to the design specifications. These bars provide additional strength to the concrete column.

- Concrete Pouring: Concrete is then poured into the assembled formwork. The smooth surface of the plastic formwork allows the concrete to flow easily, ensuring a uniform distribution. Care should be taken to avoid over – pouring or creating air pockets.

- Curing and Demolding: After the concrete has been poured, it needs to be cured according to standard construction practices. Once the concrete has reached the required strength, the plastic formwork can be easily removed. The demolding process is straightforward due to the non – stick nature of the plastic surface.

Customer Feedback on Plastic Round Column Formwork

- Positive Feedback: Many customers have praised the plastic round column formwork for its ease of use. Contractors have reported that the lightweight design and simple assembly process have reduced the time required for column construction. For example, a construction company working on a high – rise building project noted that they were able to complete the installation of plastic round column formwork 30% faster compared to using traditional formwork. Customers also appreciate the durability of the formwork, as it has proven to be a cost – effective solution in the long run. The smooth surface finish of the concrete columns produced using plastic formwork has also received positive feedback, especially in projects where aesthetics are important.

- Areas for Improvement: Some customers have suggested that manufacturers could further improve the customization options, especially for more complex or unique column designs. There have also been a few reports of minor damage to the formwork during transportation, highlighting the need for better packaging solutions. However, overall, the positive feedback far outweighs these minor concerns, and plastic round column formwork has become a popular choice in the construction industry.

In conclusion, plastic round column formwork offers a range of benefits in terms of features, sizes, and cost – effectiveness. With its ease of construction and positive customer feedback, it is a viable option for construction projects of all sizes. Whether you are working on a small residential building or a large – scale commercial development, considering plastic round column formwork for your next project could lead to significant advantages in terms of time, cost, and quality.