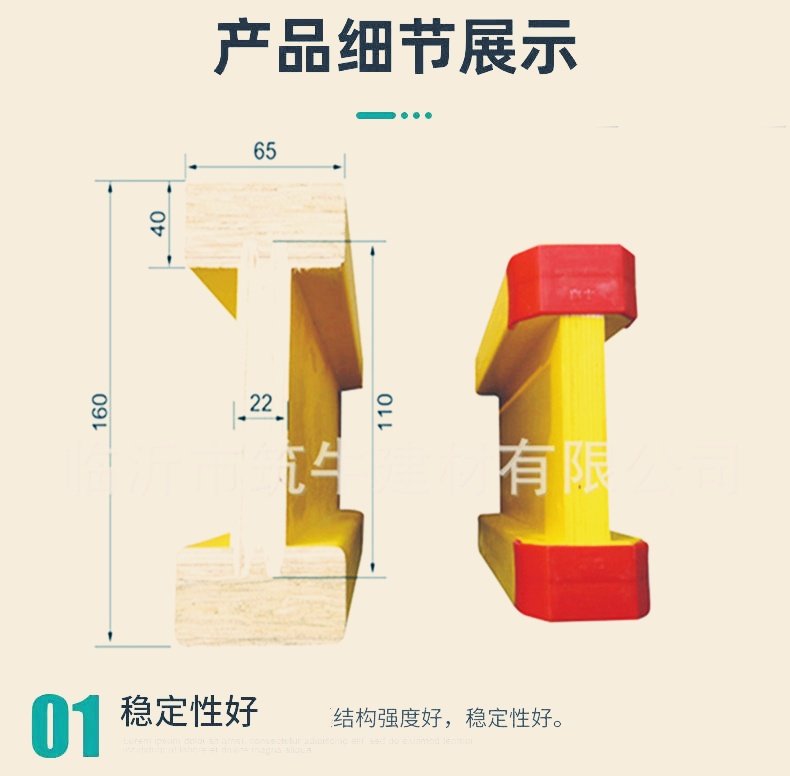

Description

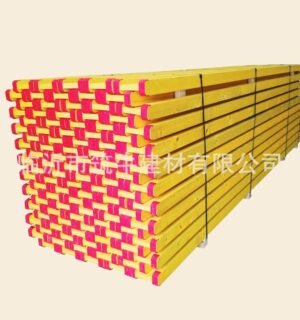

In the world of construction, furniture manufacturing, and interior design, choosing the right material is crucial to ensuring structural stability, longevity, and performance. Beam plywood stands out as a top-tier choice, renowned for its exceptional strength, remarkable durability, and versatile applications. Crafted with precision and high-quality materials, it addresses the evolving needs of professionals seeking reliable solutions for both heavy-duty and decorative projects.

1. Premium Material Composition: The Foundation of Quality

Beam plywood is engineered using a meticulous layering process that combines natural wood veneers with advanced adhesive technologies, resulting in a material that surpasses traditional solid wood in consistency and resilience.

- Multi-Layered Solid Wood Veneers: At its core, beam plywood consists of multiple thin layers (or “plies”) of high-grade hardwood or softwood veneers, such as birch, pine, poplar, or oak. These veneers are carefully selected for their uniform texture, minimal defects, and excellent mechanical properties. The number of plies varies based on the desired thickness and strength—common configurations range from 3-ply to 12-ply or more, ensuring flexibility to meet specific project requirements.

- High-Performance Adhesives: The veneers are bonded together using industrial-grade, water-resistant, or waterproof adhesives (such as phenol-formaldehyde or melamine-urea-formaldehyde resins). These adhesives not only create a strong, permanent bond between layers but also enhance the plywood’s resistance to moisture, temperature fluctuations, and chemical wear. This bonding process eliminates weak points often found in solid wood, such as knots or grain irregularities, resulting in a material with consistent strength across its entire surface.

- Eco-Friendly Options: Many manufacturers now offer beam plywood made from sustainably sourced wood (certified by organizations like FSC or PEFC) and low-VOC (volatile organic compound) adhesives. This makes it an environmentally responsible choice for projects prioritizing green building standards.

2. Exceptional Strength & Durability: Built to Last

One of the most notable advantages of beam plywood is its outstanding structural strength and long-lasting durability—qualities that make it ideal for load-bearing and high-traffic applications.

- High Load-Bearing Capacity: The cross-grain construction of beam plywood (where each layer’s wood grain is oriented perpendicular to the one above) distributes weight evenly across the material. This design resists bending, warping, and splitting, even under heavy loads. For example, 18mm thick beam plywood can support up to 50kg per square meter without deformation, making it suitable for beams, joists, and structural frames in buildings.

- Resistance to Wear & Tear: Unlike solid wood, which is prone to dents and scratches, beam plywood’s dense, layered structure offers superior abrasion resistance. It maintains its shape and appearance even in high-use environments, such as commercial furniture, flooring underlays, or shipping crates.

- Weather & Moisture Resistance: Depending on the adhesive and veneer type, beam plywood can be treated to withstand harsh weather conditions. Exterior-grade beam plywood (with waterproof adhesives and pressure-treated veneers) resists rot, mold, and water damage, making it suitable for outdoor structures like decks, fences, and shed roofs.

- Longevity: With proper maintenance, beam plywood can last for decades. Its resistance to environmental stressors and mechanical damage ensures that projects built with beam plywood retain their structural integrity and aesthetic appeal over time—reducing the need for frequent repairs or replacements.

3. Versatile Applications: From Construction to Creativity

Beam plywood’s combination of strength, durability, and workability makes it a versatile material for a wide range of industries and projects.

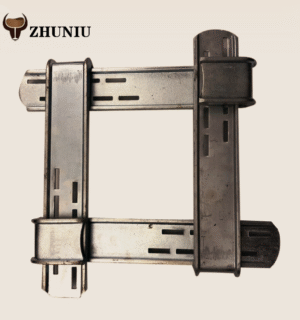

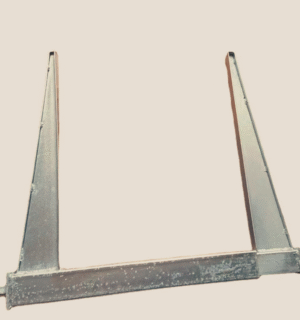

- Construction & Building: In residential and commercial construction, beam plywood is used for structural components such as floor joists, roof rafters, wall studs, and support beams. Its lightweight nature (compared to steel or concrete) simplifies transportation and installation, while its strength ensures building safety. It is also a popular choice for concrete formwork, as it can withstand the pressure of wet concrete and be reused multiple times.

- Furniture Manufacturing: Beam plywood is a favorite among furniture designers and manufacturers for creating sturdy, modern pieces. It is used to make table tops, chair frames, cabinet sides, and 书架 (bookshelves), as it can be easily cut, shaped, and finished (painted, stained, or laminated) to match any design style. Its resistance to warping ensures that furniture remains stable even in humid or dry environments.

- Interior Design & Renovation: For interior projects, beam plywood is used for wall paneling, ceiling tiles, and flooring underlays. Its natural wood texture adds warmth to spaces, while its durability makes it suitable for high-traffic areas like hallways or living rooms. It can also be used to create custom fixtures, such as room dividers or decorative accents.

- Packaging & Logistics: In the packaging industry, beam plywood is used to make heavy-duty crates, pallets, and shipping containers. Its strength and impact resistance protect fragile or heavy items (such as machinery, electronics, or artworks) during transportation, reducing the risk of damage.

- DIY & Hobby Projects: For hobbyists and DIY enthusiasts, beam plywood is an accessible and reliable material for projects like birdhouses, storage boxes, or model buildings. Its workability allows for easy cutting with basic tools, while its strength ensures that finished projects are functional and long-lasting.

Why Choose Beam Plywood?

In summary, H16/H20 beam timber plywood offers a unique blend of quality, strength, durability, and versatility that makes it a superior choice for any project requiring reliable performance. Whether you’re building a house, designing furniture, or creating a custom DIY piece, beam plywood delivers:

- Consistent strength and load-bearing capacity

- Resistance to warping, moisture, and wear

- Eco-friendly and sustainable options

- Easy workability and customization

Invest in beam plywood today, and experience the difference that a high-quality, engineered wood material can make for your project.