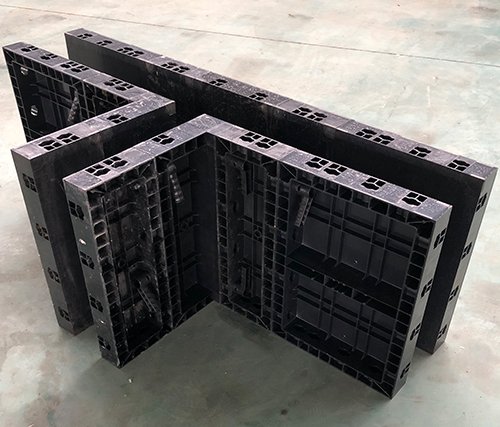

At present, plastic concrete formwork is being used in more and more construction projects and has received high praise from many construction workers.

However, there is no perfect product in the world, and plastic formwork has some disadvantages. The following are some of the disadvantages of plastic formwork summarized by our Zhuniu Formwork through communication with more than 100 construction workers on construction sites.

Disadvantages of Plastic Building Formworks:

- Initial Cost: The production cost of high-quality plastic building formworks is relatively high, which may lead to a higher initial investment compared to some traditional materials. This cost factor can be a deterrent for small-scale construction projects with tight budgets.

- Temperature Sensitivity: Plastic materials can expand and contract with changes in temperature. In extreme heat or cold conditions, this property may cause dimensional instability, affecting the accuracy of the formwork and potentially leading to concrete quality issues. For instance, in very hot weather, the formworks might expand and create gaps, allowing concrete slurry to leak.

- Limited Load-Bearing Capacity: Generally, plastic formworks have a lower load-bearing capacity compared to steel formworks. They may not be suitable for heavy-duty construction projects where large loads need to be supported, such as high-rise building foundations. Extra reinforcement or alternative support systems may be required, adding complexity and cost.

- Environmental Concerns: Although plastic formworks can be recycled, the recycling process requires proper facilities and management. Improper disposal of plastic waste can have a negative impact on the environment, contributing to pollution and waste accumulation.

However, while we have to admit that plastic formwork has some disadvantages, we cannot ignore its enormous advantages.

Advantages of Plastic Building Formworks:

- Lightweight: Plastic formworks are much lighter than traditional wooden or steel templates. This makes them easier to transport, handle, and install on construction sites, reducing labor intensity and improving construction efficiency. For example, workers can carry and position plastic formworks more quickly, saving time during the formwork erection process.

- Durable: They have good resistance to corrosion, moisture, and insects. Unlike wooden formworks that may rot or be damaged by termites, plastic formworks can maintain their structural integrity over a long period. This durability ensures a longer service life, reducing the need for frequent replacements and overall project costs.

- Smooth Surface Finish: The surface of plastic formworks is smooth, which results in a better finish for the concrete. It minimizes the need for additional surface treatments after the concrete is poured, saving both time and cost. The smooth surface also allows for easier demolding, preventing damage to the concrete structure.

- Customizable: Plastic can be molded into various shapes and sizes, offering great flexibility in design. Contractors can order formworks that are specifically tailored to the unique requirements of a project, facilitating the construction of complex architectural features.

For any product, as long as its advantages are significant enough, the disadvantages can almost be ignored. The advantages of plastic formwork, such as a high number of reuse cycles and light weight, are deeply favored by construction workers. Therefore, plastic formwork will definitely become more and more popular in the future. If you want a price list and samples of plastic formwork, you can contact me directly.

Wechat&Whatsapp:+86 180-5453-6350

or Please leave your contact information below, and our sales manager will contact you promptly.

Contact Information

- Mrshao1017@gmail.com

- (+86)180 5453 6350

Opening Hours

Get In Touch With Us!

Complete control over products allows us to ensure our customers receive the best quality prices and service. Your email address will not be published.