What can I use for a round concrete form?

Round concrete formwork is a critical component in construction projects involving circular structures such as columns, silos, water tanks, and tunnels. Among the various materials used for round concrete formwork, wood, plastic, and steel stand out, each offering unique advantages tailored to specific project requirements. Understanding the strengths of each type helps construction teams make informed decisions, ensuring efficiency, quality, and cost-effectiveness.

The Advantages of Wooden Round Concrete Formwork

Wooden round concrete formwork has long been a staple in construction due to its exceptional versatility and ease of use. Crafted from high-quality plywood or timber, these formworks excel in adapting to diverse project needs. One of its key advantages lies in its lightweight nature, which significantly simplifies transportation and on-site handling. Construction workers can easily maneuver wooden formworks without relying on heavy machinery, reducing labor intensity and saving time during installation and dismantling.

Wooden formworks also offer excellent workability. Carpenters can quickly cut, shape, and customize them to match specific circular dimensions, making them ideal for projects with unique radius requirements, such as decorative columns in architectural designs or curved retaining walls. This flexibility eliminates the need for expensive custom fabrication, allowing for on-the-fly adjustments that keep projects on schedule.

In terms of cost, wooden round formworks are often more budget-friendly compared to their steel counterparts, especially for small to medium-sized projects. They are readily available in most construction markets, reducing procurement lead times. While wooden formworks may have a shorter lifespan than steel ones, their lower initial investment makes them a cost-effective choice for projects with limited budgets or one-time use scenarios, such as temporary structures or short-term construction contracts.

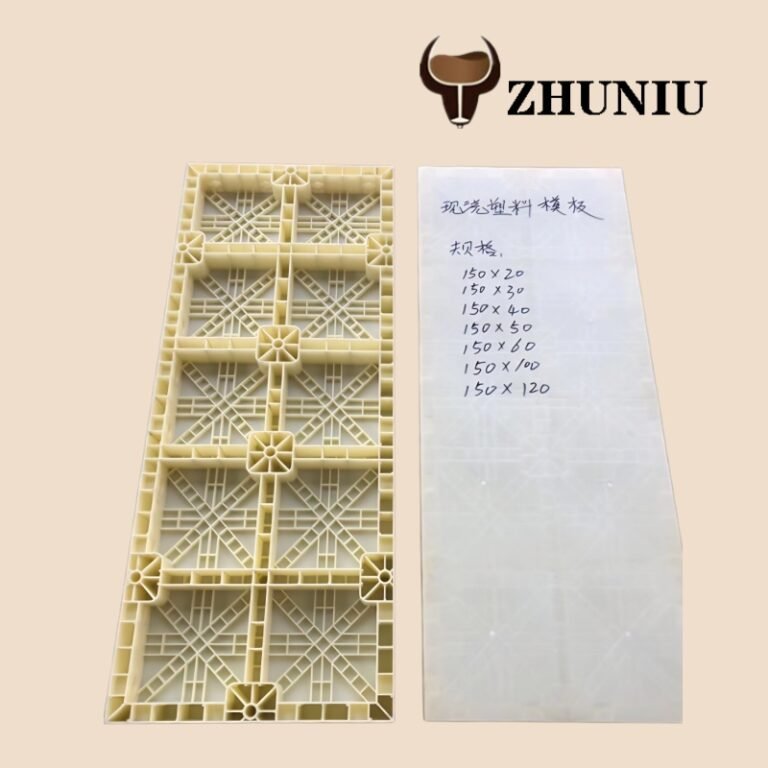

The Advantages of Plastic Round Concrete Formwork

Plastic round concrete formwork has gained popularity in recent years, thanks to its modern design and practical benefits. Made from high-density polyethylene (HDPE) or polypropylene, these formworks are lightweight yet durable, striking a balance between portability and longevity. Their smooth surface finish is a standout feature—when the concrete sets and the formwork is removed, it leaves a sleek, even surface on the round structure, minimizing the need for post-pouring polishing or finishing work. This not only saves time but also reduces the cost of additional labor and materials for surface treatment.

Water resistance is another major advantage of plastic round formwork. Unlike wood, which can absorb moisture and warp, plastic is impervious to water, making it ideal for projects involving wet concrete or outdoor environments with frequent rain. This resistance to water damage ensures that the formwork maintains its shape and structural integrity throughout the pouring and curing process, resulting in consistent, high-quality concrete rounds.

Plastic formworks are also easy to clean and maintain. After use, they can be quickly rinsed with water to remove concrete residue, and their non-stick surface prevents stubborn buildup. This ease of maintenance extends their lifespan, allowing them to be reused multiple times—often 50 times or more with proper care. While the initial cost of plastic formwork may be higher than that of wood, its reusability makes it a cost-effective option in the long run, especially for large-scale projects or construction companies with ongoing needs for round concrete structures.

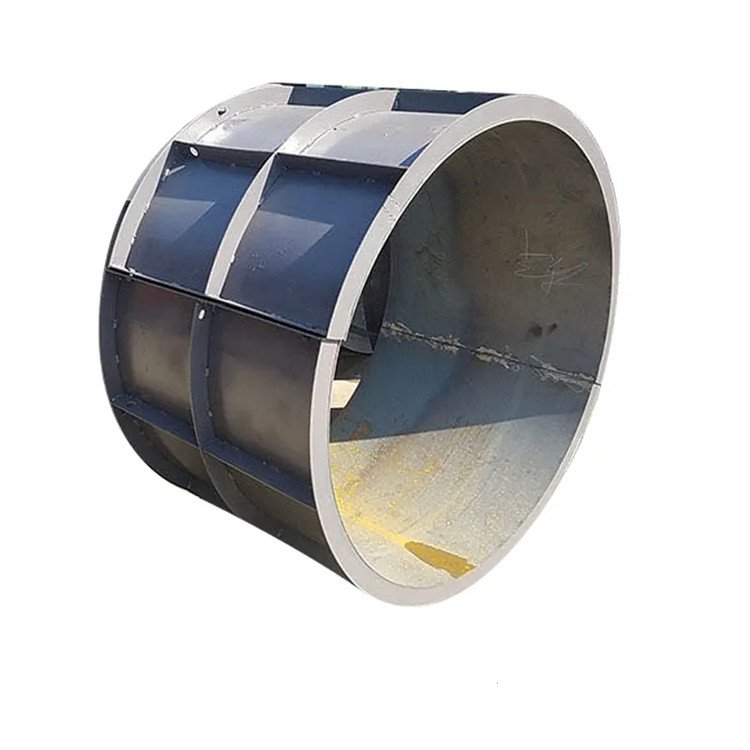

The Advantages of Steel Round Concrete Formwork

Steel round concrete formwork is the go-to choice for projects demanding exceptional strength, durability, and precision. Constructed from high-grade steel alloys, these formworks are built to withstand extreme pressure and heavy loads, making them ideal for large-scale industrial projects, such as bridge piers, high-rise building columns, and massive water treatment facilities.

One of the most significant advantages of steel formwork is its unparalleled durability. It can withstand repeated use in harsh construction environments, including exposure to extreme temperatures, heavy concrete pressure, and rough handling. Unlike wood, which may splinter or warp over time, or plastic, which can crack under intense stress, steel formwork maintains its shape and structural integrity for decades, making it a long-term investment for construction companies.

Steel round formwork also offers superior precision. Its rigid structure ensures that the concrete round maintains exact dimensions and a smooth, uniform surface, which is critical for projects with strict engineering requirements. Additionally, steel formwork is fire-resistant, adding an extra layer of safety to construction sites. While its initial cost is higher than that of wood or plastic, its reusability, low maintenance needs, and ability to deliver consistent results make it a cost-effective choice for large, high-demand projects.

In conclusion, wooden, plastic, and steel round concrete formworks each have distinct advantages that cater to different construction needs. Wooden formworks excel in versatility and affordability for small to medium projects; plastic formworks shine in water resistance, ease of maintenance, and surface quality; and steel formworks stand out in strength, durability, and precision for large-scale industrial applications. By selecting the right type of formwork, construction teams can optimize efficiency, reduce costs, and ensure the successful completion of round concrete structures.

We are a professional manufacturer specializing in customizing and producing circular concrete formworks. Whether you need wooden, plastic, or steel circular molds, we can provide you with suitable circular formwork products with high cost performance. Please feel assured that we will give you the best discount.