In the dynamic field of construction, the search for efficient, cost – effective, and versatile materials has always been a driving force for innovation. Among the various components that contribute to the success of concrete construction projects, shuttering plays a crucial role. It serves as a temporary structure that holds fresh concrete in place until it hardens and gains sufficient strength to support its own weight and any applied loads. In recent years, plastic concrete formwork has emerged as a game – changer, gradually replacing traditional materials like wood, steel, and aluminum. This essay will delve into three key advantages of plastic shuttering for concrete construction: its lightweight nature and ease of operation, its comprehensive range of sizes and shapes, and its cost – effectiveness with high reusability.

lightweight

First and foremost, plastic shuttering concrete stands out due to its lightweight characteristic, which significantly simplifies the construction process and enhances operational efficiency. Unlike steel shuttering, which requires heavy – duty lifting equipment and a large number of workers to handle, plastic shuttering is much lighter. A typical plastic shuttering panel of standard size(1200*1000mm)weighs only about 20 kilograms, while a similar – sized steel panel can weigh over 50 kilograms.

This light weight means that construction workers can carry and install the plastic shuttering manually, without relying on expensive machinery such as cranes or forklifts. This not only saves time spent on equipment setup and operation but also reduces the risk of workplace accidents caused by the handling of heavy materials. For example, in high – rise building construction, where the transportation of materials to upper floors is a challenge, the lightweight of plastic shuttering makes it easy to be lifted using simple hoists or even carried by workers via staircases. Moreover, the installation process of plastic shuttering is straightforward. It comes with pre – designed interlocking systems that allow panels to be connected quickly and securely.

Workers do not need to have extensive professional skills to assemble the shuttering, which shortens the training time and ensures a smooth construction workflow.

flexible

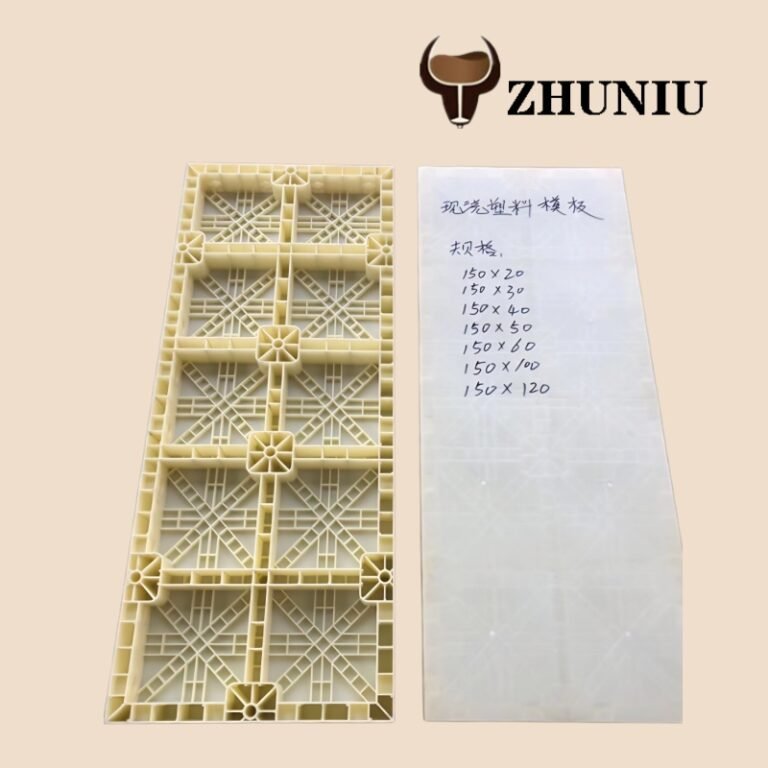

Secondly, plastic shuttering offers an extensive variety of sizes and shapes, making it highly adaptable to different concrete construction needs, including the formation of square columns, circular columns, and walls. Traditional shuttering materials often have limitations in terms of customization. For instance, wood shuttering may warp or crack when cut into complex shapes, and steel shuttering requires expensive and time – consuming fabrication to achieve non – standard sizes. In contrast, plastic shuttering is manufactured using injection molding or extrusion processes, which enable the production of panels in almost any size and shape according to specific project requirements.

For square columns, plastic shuttering panels can be easily cut to the exact dimensions of the column cross – section, and their interlocking design ensures that the corners are sharp and well – defined. When it comes to circular columns, plastic shuttering provides curved panels that fit perfectly together to form a smooth circular surface, eliminating the need for on – site shaping and reducing the risk of concrete leakage. For wall construction, plastic shuttering is available in large – sized panels that cover a wide area, minimizing the number of joints and improving the overall strength and appearance of the concrete wall. Additionally, plastic shuttering can be customized to include features such as grooves or protrusions to create decorative patterns on the concrete surface, adding aesthetic value to the construction project without increasing the complexity of the shuttering installation.

cost – effective

Last but not least, plastic shuttering is highly cost – effective, primarily due to its low initial price and high reusability, which significantly reduces the overall construction cost. Compared to steel shuttering, which has a high initial cost, plastic shuttering is more affordable. A standard plastic shuttering panel costs approximately 30 – 50% less than a similar – sized steel panel, making it a more economical choice for construction projects with tight budgets.

Furthermore, plastic shuttering has an excellent service life and can be reused multiple times. Unlike wood shuttering, which is prone to rot, mold, and damage after a few uses, and steel shuttering, which is susceptible to rust and corrosion, plastic shuttering is resistant to water, chemicals, and physical wear. With proper maintenance (such as cleaning and storing in a dry place after use), plastic shuttering can be reused up to 50 – 100 times, depending on the quality of the material and the construction conditions. This high reusability means that the average cost per use of plastic shuttering is much lower than that of traditional shuttering materials.

For example, if a plastic shuttering panel costs \(50 and can be reused 50 times, the cost per use is only \)1. In contrast, a wood shuttering panel that costs \(20 but can only be reused 5 times has a cost per use of \)4. Over the course of a large – scale construction project, the savings in shuttering costs can be substantial, which can be allocated to other important aspects of the project, such as improving the quality of concrete or investing in advanced construction technologies.

Conclusion

plastic shuttering has revolutionized the concrete construction industry with its lightweight and easy – to – operate features, comprehensive range of sizes and shapes, and cost – effectiveness with high reusability. It not only simplifies the construction process, improves work efficiency, and enhances the quality of concrete structures but also helps construction companies reduce costs and increase profits. concrete formwork manufacturers As the construction industry continues to pursue sustainable and efficient development, plastic shuttering is expected to become even more popular and widely used in various construction projects, from residential buildings to large – scale infrastructure projects. Its unique advantages make it a reliable and promising choice for the future of concrete construction.

leave your contact information, Please feel assured that we will give you the best discount.