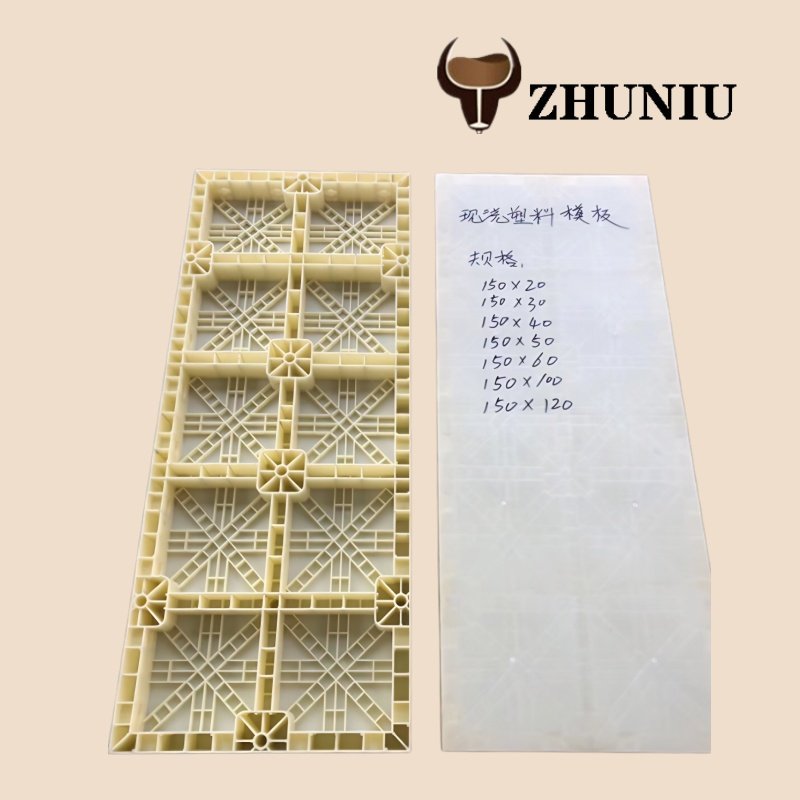

Hey everyone! Today, I’m excited to introduce you to a revolutionary product that’s been shaking up the construction industry — plastic wall concrete formwork. If you’ve ever been involved in concrete pouring projects, you know how crucial formwork is, and this innovative option is here to solve many of the traditional pain points. Let’s dive into its three standout advantages.

First , let’s talk about its intelligent handle connection design.

Unlike traditional wooden or steel formwork that requires complicated fastening with screws, nails, this plastic wall formwork comes with integrated, sturdy handles. The connection process is as simple as aligning the grooves of two formwork panels, locking them together via the handle, and giving it a quick, firm twist. No extra tools are needed, no time wasted on fumbling with small parts. This design not only cuts down the assembly time by over 50% compared to conventional options but also ensures the formwork stays tightly sealed during pouring, effectively preventing concrete leakage and ensuring a smooth, uniform finish of the concrete structure.

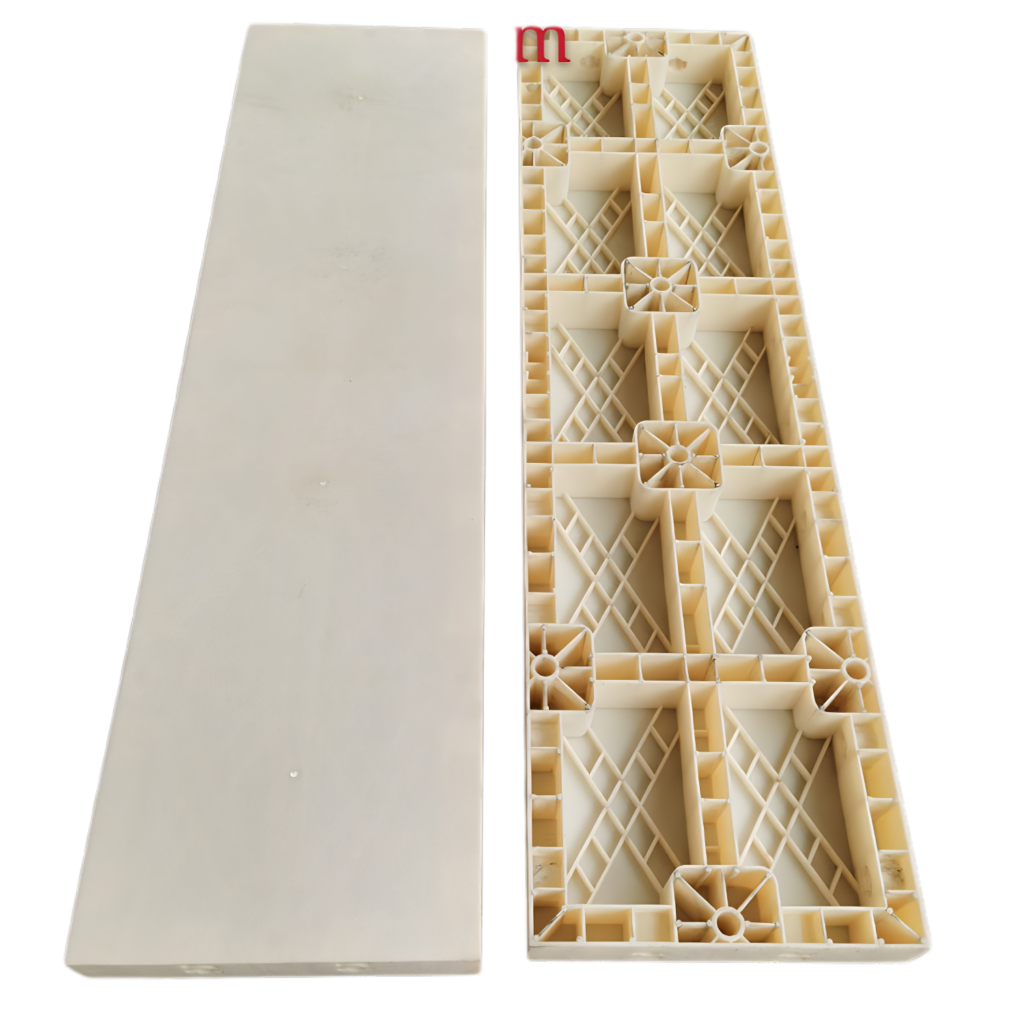

Second, this plastic concrete formwork is surprisingly lightweight.

We all know steel formwork is heavy and hard to move it, often requiring cranes or multiple workers to transport and install. But this plastic version is made from high-strength, lightweight pp materials. A single panel of standard size can be easily lifted and carried by just one worker. This lightweight feature drastically reduces labor intensity, speeds up on-site transportation and installation, and is especially ideal for projects in narrow spaces or high-rise buildings where heavy machinery can’t easily reach.

Third, let’s focus on its durable and tough surface.

The surface of this plastic wall formwork is treated with a special anti-corrosion and anti-wear coating. It’s resistant to water, chemical corrosion from concrete additives, and scratches from on-site construction. Unlike wooden formwork that warps, rots, or gets damaged after just a few uses, this plastic formwork can be reused over 50 times without losing its shape or smoothness. Even after repeated use, the surface remains sleek, which means the concrete cast with it has a high-quality, polished appearance, eliminating the need for post-pouring grinding and polishing in most cases, saving both time and cost.

To sum it up, with its hassle-free handle connection, labor-saving lightweight design, and long-lasting durable surface, plastic concrete formwork is truly a cost-effective, efficient alternative for modern construction. Whether you’re working on a small residential project or a middle-scale commercial building, it’s definitely worth a try!