When it comes to choosing formwork solutions for construction, cost-effectiveness, usability, and durability are top priorities for contractors and project managers. A common question that arises is: How much is plastic formwork per m²? The answer lies in a balance of upfront investment and long-term savings—plastic formwork typically costs around $25 per square meter, a price point that becomes even more compelling when considering its exceptional performance and multiple advantages.

First and foremost, the 25 per m² cost is justified by its outstanding reusability.

Unlike traditional wooden formwork, which often deteriorates after 5-10 uses, high-quality plastic formwork can be **recycled and reused over 50 times** with proper maintenance. This means the actual cost per use drops significantly: dividing the initial \)25 by 50 uses results in a mere $0.5 per m² per project. For small to medium-scale construction projects—such as residential buildings, small commercial complexes, or interior renovations—this translates to substantial cost savings over the entire project lifecycle, eliminating the need for frequent replacements of disposable or low-durability formwork materials.

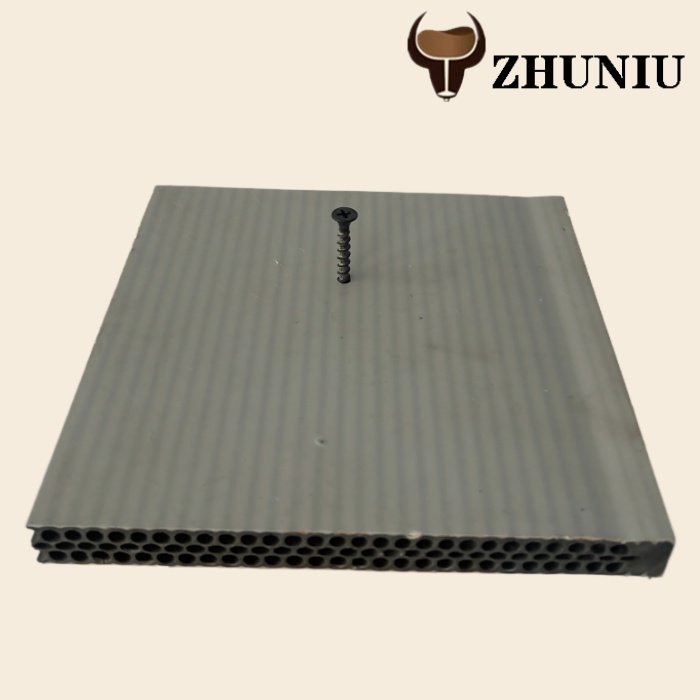

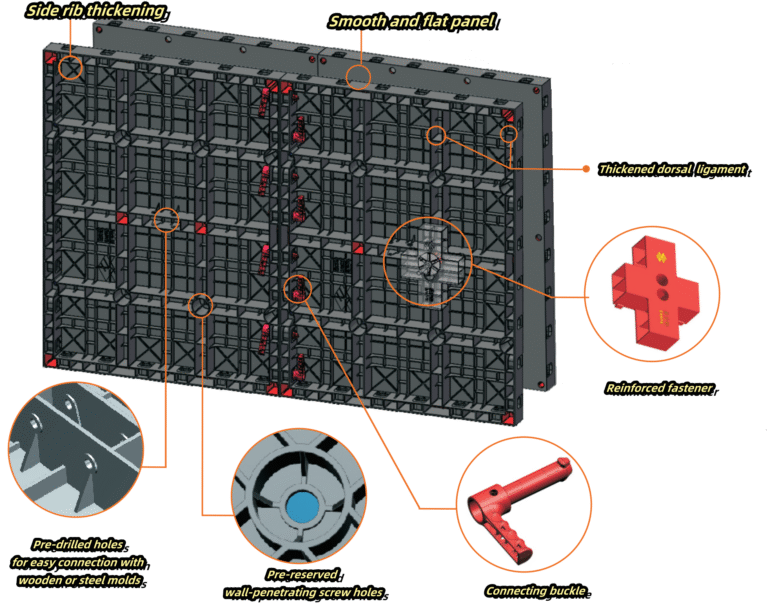

Another key advantage of plastic formwork is its pin connection system

which simplifies installation and disassembly. The pin-and-buckle design allows for quick assembly without requiring complex tools or skilled labor, reducing construction time and labor costs. Compared to steel formwork, which relies on heavy bolts and welding, or wooden formwork that needs cutting and fitting, plastic formwork’s pin connection ensures precise alignment, consistent concrete finishing, and minimal material waste. This efficiency is particularly valuable for small to medium projects, where tight schedules and limited labor resources are common challenges.

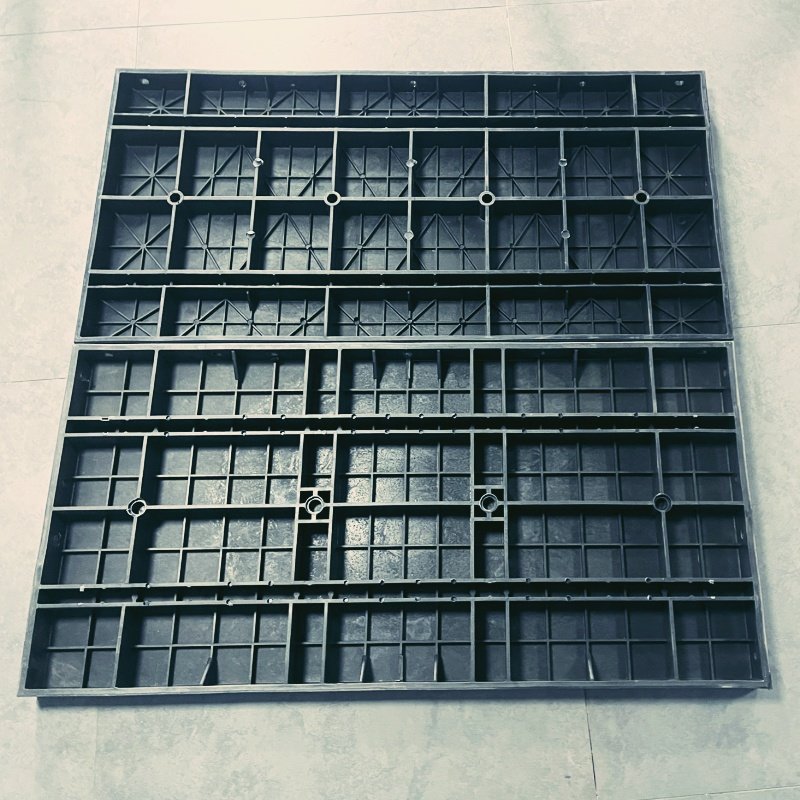

Additionally, plastic formwork boasts an ultra-lightweight design

typically weighing 30-50% less than steel formwork and 20-30% less than traditional plywood. Its light weight not only eases transportation and on-site handling (reducing the risk of worker fatigue or injury) but also eliminates the need for heavy lifting equipment, further cutting down on project costs. For small construction teams or projects with limited access to heavy machinery, this advantage is game-changing.

Beyond cost savings and ease of use, plastic formwork offers other benefits that enhance its suitability for small to medium-scale projects: it is resistant to water, rot, and corrosion, ensuring consistent performance even in harsh construction environments; its smooth surface produces high-quality concrete finishes, reducing the need for post-construction plastering or refinishing; and it is environmentally friendly, as its long service life reduces waste compared to single-use or short-lived formwork materials.

In summary, at approximately $25 per square meter, plastic formwork is a cost-effective investment for small to medium-scale construction projects. Its ability to be reused over 50 times, combined with the efficiency of pin connections, lightweight design, and durable performance, delivers significant long-term savings in labor, material replacement, and equipment costs. Whether you’re building a residential house, a small office building, or renovating an interior space, plastic formwork provides a reliable, efficient, and economical solution that meets the unique needs of smaller construction projects.