Plastic formwork has emerged as a cost-effective and sustainable alternative to traditional plywood, steel, and aluminum systems in concrete construction. Its pricing varies significantly based on material quality, reuse capacity, and performance, with three primary tiers dominating the market. Below is a detailed analysis of typical costs and value propositions.

1. Market Price Tiers of Plastic Wall Formwork

Plastic concrete wall formwork is categorized by lifecycle value, with three distinct tiers aligning with project scale and budget requirements:

Entry-Level (Cost-Effective)

- Unit Price: $25 per square meter

- Reuse Cycles: Approximately 30 times

- Per-Cycle Cost: ~$0.83 per square meter

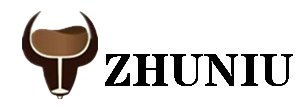

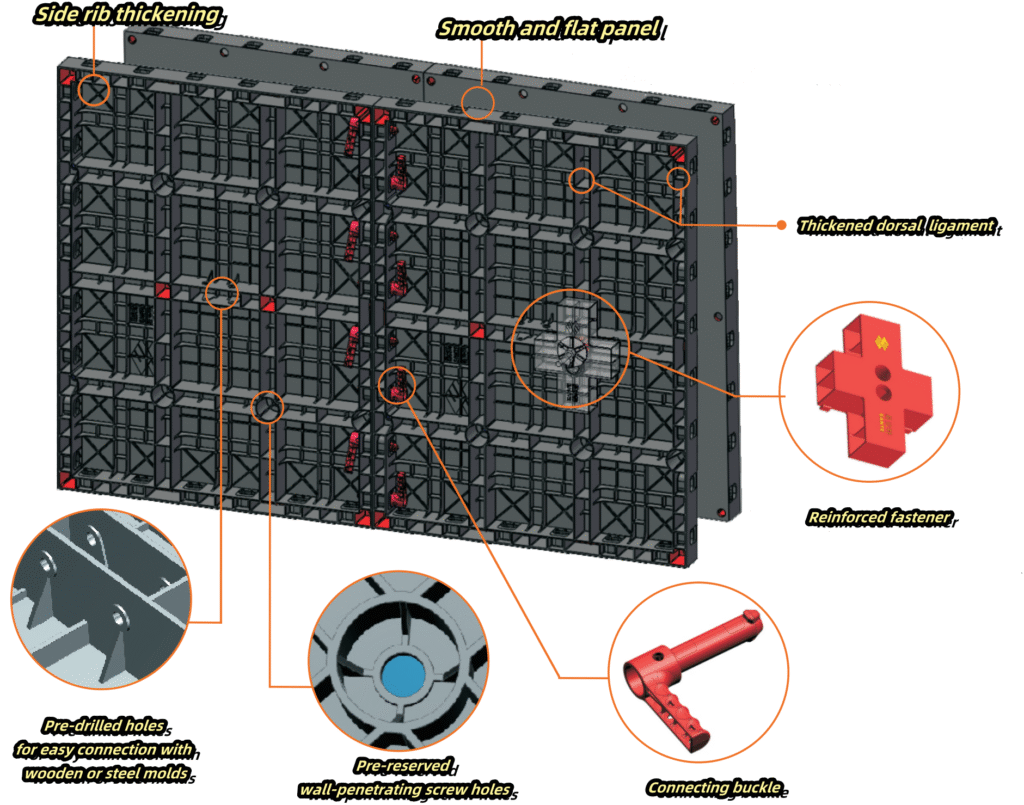

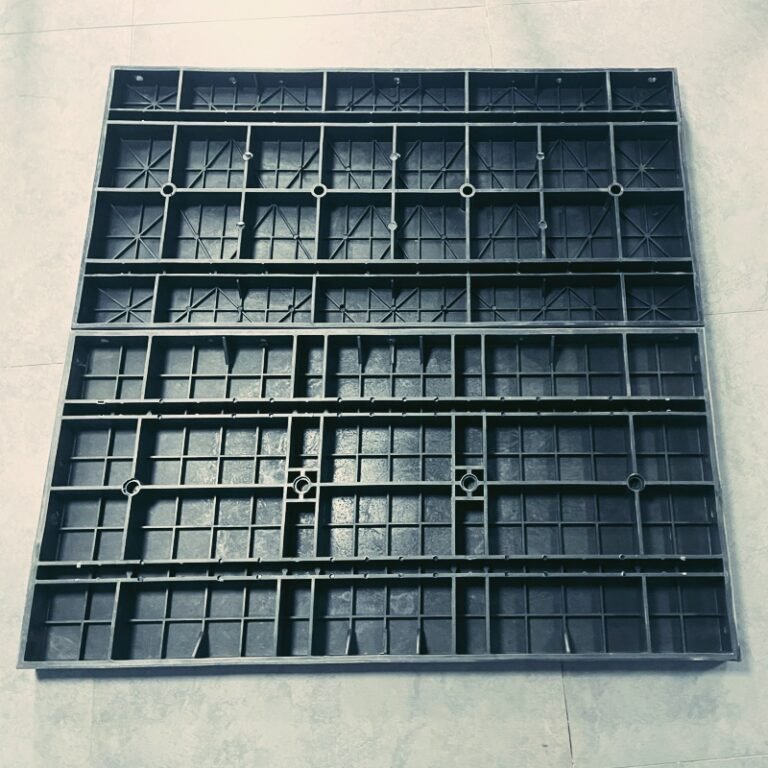

- Material Profile: Typically made of basic polypropylene (PP) or glass fiber mat reinforced thermoplastic (GMT) . Lightweight (0.4g/cm³) and easy to handle, it eliminates the need for form oil .

- Best For: Short-term single projects, small-scale residential buildings, or projects with frequent design changes.

Mid-Range (Performance-Grade)

- Unit Price: $38 per square meter

- Reuse Cycles: Up to 100 times

- Per-Cycle Cost: $0.38 per square meter

- Material Profile: Enhanced PP with glass fiber reinforcement, offering higher flexural modulus and moisture resistance . Compatible with fast-track construction, reducing cycle time by 40% compared to plywood .

- Best For: Mid-rise residential complexes, commercial buildings, and projects requiring 5–10 repeated uses.

High-End (Premium)

- Unit Price: $55 per square meter

- Reuse Cycles: 200+ times

- Per-Cycle Cost: $0.275 per square meter

- Material Profile: Advanced PP+long glass fiber composite , delivering exceptional durability and concrete surface finish (eliminating secondary plastering). Recyclable with a residual value of ~$30 per square meter .

- Best For: Large-scale infrastructure, high-rise buildings, and developers managing multi-project portfolios (6+ buildings).

2. Cost Drivers and Long-Term Value

Initial investment in plastic formwork is 2–3 times higher than plywood , but its reuse capacity transforms long-term economics:

- Lifecycle Cost Advantage: For a 33-story building, mid-range plastic formwork reduces total costs by 65% compared to plywood over 3 projects .

- Hidden Savings: No form oil expenses, lower labor costs (lightweight design), and reduced waste disposal fees .

- Sustainability Value: Plastic formwork generates 20% less embodied energy than steel and has the lowest carbon emissions among common formwork materials .

3. Comparison with Alternative Systems

| System | Initial Cost ($/㎡) | Reuse Cycles | Per-Cycle Cost ($/㎡) | Key Limitation |

| Plywood | $8–12 | 6–8 | $1.25–1.50 | High waste, frequent replacement |

| Steel | $80–120 | 50–100 | $1.00–1.60 | Heavy (requires machinery) |

| Aluminum | $140–180 | 100+ | $1.40–1.80 | Rigid (poor for 异形 structures) |

| Premium Plastic | $55 | 200+ | $0.275 | Higher upfront cost |

Conclusion

Plastic formwork’s cost ranges from \(25 to \)55 per square meter, with value determined by reuse potential. While entry-level options suit short-term needs, mid-range and premium tiers deliver superior long-term savings—especially for developers prioritizing efficiency and sustainability. As noted in lifecycle assessments , plastic formwork outperforms traditional systems in both economic and environmental metrics when reuse is maximized.