Circular wooden plywood formwork plays a crucial role in construction, especially for concrete pouring of circular structures like columns and pipelines. Its production involves several precise steps, with raw material cutting, template hot pressing, tongue-and-groove cutting, and edge trimming being the core processes.

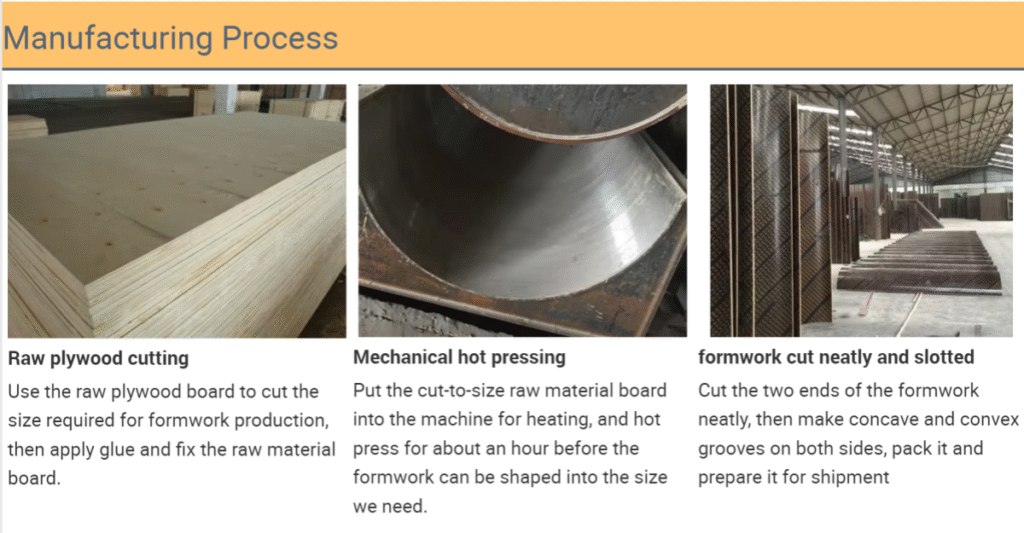

The first step is raw material cutting. High-quality plywood or multi-layered wood panels are selected as the base material. Workers measure and mark the panels according to the required diameter and length of the circular formwork. Advanced cutting machines are then used to cut the panels into strips of specific widths. This step requires high precision to ensure that each strip has consistent dimensions, which lays the foundation for the subsequent forming of the circular shape. Any error in cutting will directly affect the accuracy of the final product.

After cutting, the strips enter the template hot pressing stage. The wooden strips are arranged in a circular mold according to the designed curvature. Under high temperature and pressure, the strips are bonded together using eco-friendly adhesives. The hot pressing process not only shapes the strips into a circular form but also enhances the overall strength and water resistance of the formwork. The temperature and pressure parameters are strictly controlled to ensure the adhesives fully cure and the wood fibers bond tightly.

Next comes the tongue-and-groove cutting process. Specialized machines cut concave grooves on one end of the circular formwork and corresponding convex grooves on the other end. These grooves allow multiple formwork sections to be tightly connected during construction, preventing concrete leakage. The depth and width of the grooves must be precisely calibrated to ensure a seamless fit between adjacent formwork pieces. This step is vital for maintaining the structural integrity of the formwork during concrete pouring.

The final key step is edge trimming. After hot pressing and groove cutting, the edges of the circular formwork may have burrs or irregularities. Circular saws or edge-trimming machines are used to trim the edges, ensuring the formwork has smooth and neat edges. Workers also check the diameter and roundness of the formwork during this stage, making minor adjustments if necessary to meet the strict construction standards.

Through these four essential processes, raw wooden materials are transformed into high-quality circular wooden formwork, providing reliable support for efficient and high-quality construction projects.