In construction, the selection of formwork has a significant impact on project quality, cost and progress. As common formwork types, circular wooden formwork, circular plastic formwork and circular steel formwork each have unique advantages and disadvantages.

Circular Wooden Formwork

Advantages

Lightweight: Generally weighing about 13kg per square meter, it can be moved and installed manually without large lifting equipment, greatly improving the efficiency of formwork installation. For example, in construction sites with limited space where large equipment is difficult to access, this advantage of wooden formwork is particularly prominent.

(my factory worker can easily carry a piece of circular wooden formwork alone.)

Flexible customization: With complete specifications, it can be produced in any specification according to design drawings. At present, any size with a diameter of 100mm can be customized and produced.The production cycle is short, and the overall transportation and installation can be completed within 4-5 working days. For the construction of special-shaped cylindrical columns, wooden formwork can be quickly processed into the required shape, reducing construction time and ensuring project progress.

Good air permeability and demoulding property: It has good air permeability, and the epoxy resin crystal surface makes demoulding easy (only 1/7 of that of steel formwork), which can shorten the concrete setting time, ensure the high-quality forming effect of concrete products, and make the surface of the poured object smooth and beautiful. This can eliminate the secondary plastering process and directly apply decorative veneers, reducing the construction period by 30%.

Good thermal insulation performance: It is conducive to winter construction, preventing the generation of bubbles and cracks, and effectively controlling common quality problems.

Disadvantages

Relatively low durability: Although the number of reused can generally reach more than 10 times, it has limited service life compared with steel formwork. After multiple uses, the formwork surface may be worn or cracked, affecting the forming quality of concrete.

Limited strength: For the construction of some large and ultra-high cylindrical columns, it may be insufficient in withstanding the lateral pressure of concrete, requiring denser support and reinforcement.

Environmental issues: Using wood as raw material, large-scale use may impose certain pressure on forest resources.

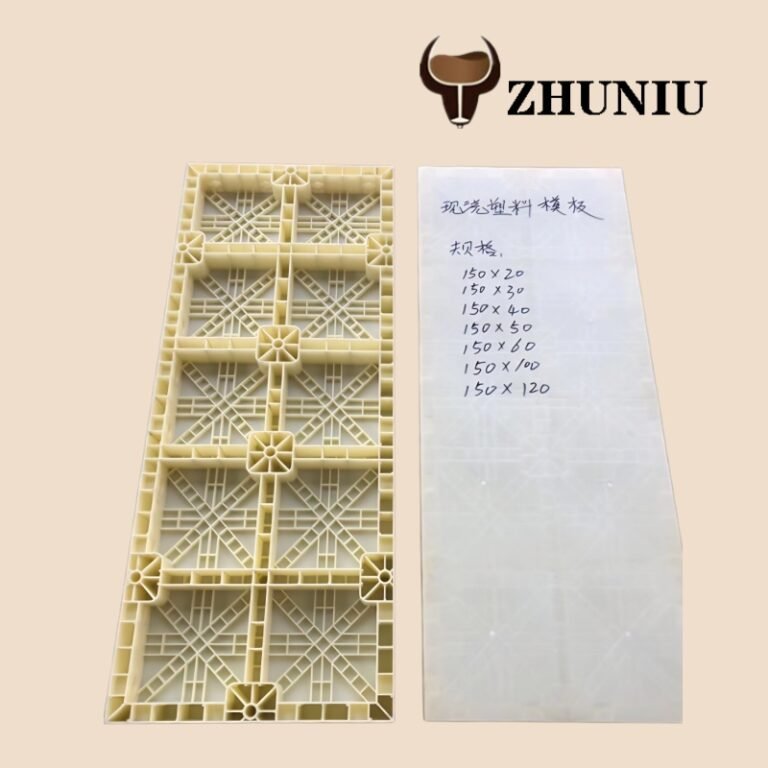

Circular Plastic Formwork

Advantages

Smooth and clean surface: The splicing is tight and flat, and the concrete structure surface after demoulding has high precision and smoothness, eliminating the need for secondary plastering and saving labor and materials.

Lightweight and easy to install: With light weight and strong process adaptability, it can be sawed, planed, drilled and nailed, and can be freely combined into any geometric shape to meet the formwork needs of buildings with various shapes. For example, in the construction of circular buildings with complex shapes, plastic formwork can easily be spliced into the required shape.

Convenient demoulding: Concrete does not stick to the formwork surface, requiring no release agent, enabling easy demoulding and ash cleaning.

Stable and weather-resistant: With high mechanical strength, it does not shrink, swell, crack or deform in temperature conditions from -20℃ to +60℃, featuring stable dimensions, alkali resistance, corrosion resistance, flame retardancy, waterproofing, and resistance to rats and insects.

Recyclable: All waste materials and used formwork can be recycled and reprocessed, achieving zero waste discharge and conforming to environmental protection concepts.

Considerate design: For example, the circular hole plastic formwork adopts a combination of two rows of small circular holes + a small elliptical hollow hole in the middle, inheriting the arch mechanical principle of ancient building bridges to increase the overall bearing strength of the formwork, and the middle small elliptical hole facilitates nail insertion during formwork splicing.

Disadvantages

Higher cost: Due to factors such as raw materials and production processes, its price is relatively higher than that of wooden formwork. Although the multiple reused can reduce the single-use cost, the upfront investment is large. –

Insufficient rigidity: When withstanding large lateral pressure of concrete, it is more prone to deformation compared with steel formwork, affecting the dimensional accuracy of cylindrical columns.

click it know more detail about circular plastic formwork!

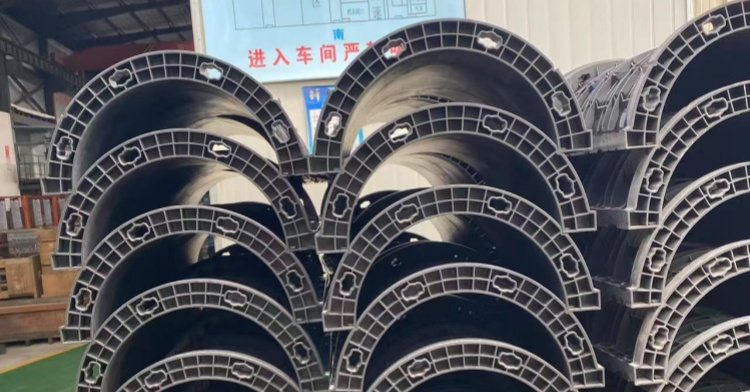

Circular Steel Formwork

Advantages

High precision and structural stability: Processed by CNC machine tools, the roundness deviation ≤1.5mm, and the perpendicularity error ≤1/1000, which can accurately control the diameter, perpendicularity and surface flatness of piers (error ≤2mm), ensuring uniform axial force on piers and reducing the risk of eccentric load in the later stage.

Efficient construction and schedule optimization: With modular design (such as 1/2 or 1/4 arc segments), it supports mechanical hoisting and splicing, and the installation time for a single section of formwork ≤1 hour, improving efficiency by 50% compared with wooden formwork. It can withstand the lateral pressure of fresh concrete, supporting one-time pouring height of 6-9 meters and reducing layered pouring joints.

Long-term economy and environmental benefits: High-quality steel formwork can be reused 200-300 times, with the single-use cost diluted to 5-8 yuan/㎡ (the single-use cost of wooden formwork is about 30 yuan/㎡). The rental cost is low, and replacing wooden formwork can reduce forest resource consumption.

Strong risk resistance: It has strong adaptability to extreme environments. Under low temperature of -30℃ or high temperature, the thermal deformation coefficient of steel formwork ≤0.01%, avoiding concrete cracking caused by temperature changes. The wind and earthquake resistance design enables it to withstand 8-level wind load and horizontal force of seismic intensity.

Disadvantage

Heavy weight: Generally, the weight of 5mm thickness is 85-100kg/㎡, requiring large machinery for handling and hoisting, which has high requirements for construction sites and equipment, and is inconvenient to operate with poor flexibility.

High production cost: It needs welding and shaping, with complex processes and high costs. Applying release agent each time increases construction procedures and costs.

Long customization cycle: The dimensions are mostly standard specifications. When customizing non-standard specifications, it takes a long time and is difficult to quickly meet urgent construction needs.

We look forward to your kind inquiries at any time if you find our products satisfactory.

You can enjoy 5% discount on your initial order.

- Email: kevin@zhuniuformwork.com

- TEL: (+86) 180-6315-9896 Wechat

- Whatsapp: (+86) 180-5453-6350