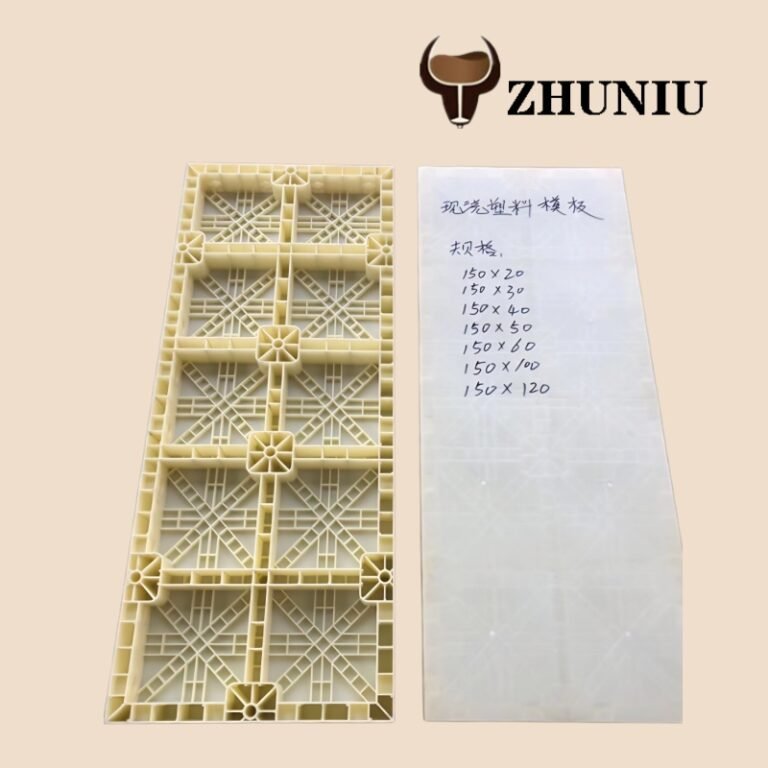

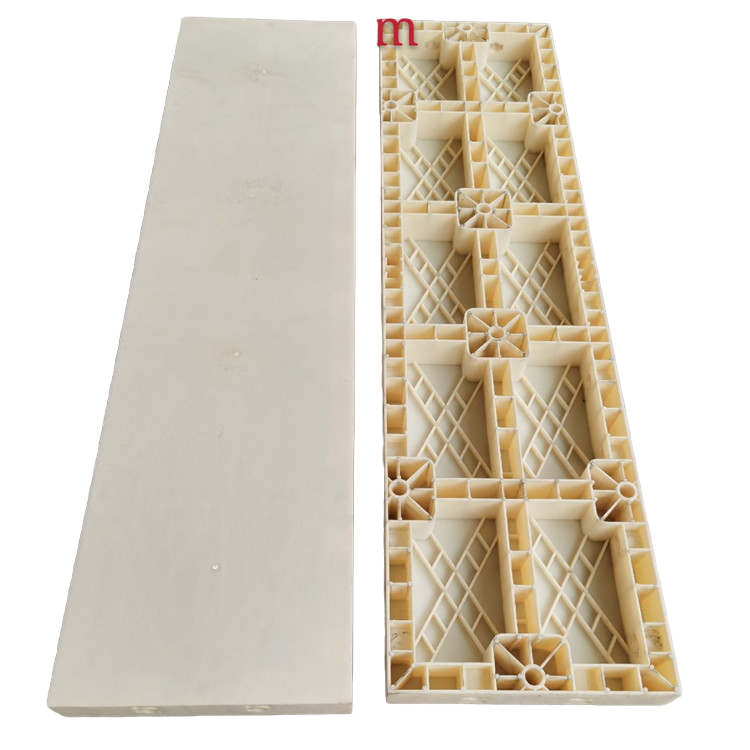

- What is plastic shuttering?

Plastic shuttering refers to reusable, lightweight formwork made from high-density polyethylene (HDPE) or polypropylene. It is widely used in concrete construction to shape and support wet concrete until it cures into a solid structure.

Compared to traditional wood or steel shuttering, it offers advantages like corrosion resistance, low maintenance, and ease of installation. Its smooth surface ensures a polished finish on concrete, reducing the need for post-casting finishing work. Suitable for beams, columns, slabs, and walls, plastic shuttering is eco-friendly due to its long service life and recyclability, making it a cost-effective choice for modern building projects.

- Shuttering formwork connected by handle in construction

- What’s the advantage of shuttering formwork?

Strength and Stability

You need strong and stable formwork to keep your project safe. The formwork must hold the weight of wet concrete, workers, and equipment. If the formwork bends or moves, the concrete shape will not be correct. You should check that the material can handle dead loads, live loads, and even wind or rain. Good formwork stays in place and keeps its shape until the concrete sets. Always look for formwork that meets industry standards for strength and stability.

Durability

Durability means the formwork lasts through many uses and tough weather. Steel and aluminum formwork can be used many times and need little care. Timber formwork costs less at first but wears out quickly and needs more repairs. The table below shows how different materials compare:

Cost

Formwork can be 35-40% of your total concrete cost. You should think about material, labor, and how many times you can reuse the formwork. Modular and reusable systems save money on big jobs. For small projects, timber or rental options may work better. Remember, higher quality formwork can lower costs in the long run by reducing repairs and waste.

Safety

Safety matters for every job. Choose formwork that is easy to set up and take down. Make sure it does not slip or fall during use. Good formwork protects workers and helps prevent accidents. Always follow local rules and check that your formwork is stable in all weather.

Versatility

You want formwork that fits your project’s needs. Some jobs need simple shapes, while others need curves or special designs. Steel and plastic systems work well for big or repeat jobs. Timber and plywood are better for custom shapes. The best concrete formwork is the one that matches your project size, shape, and weather conditions.

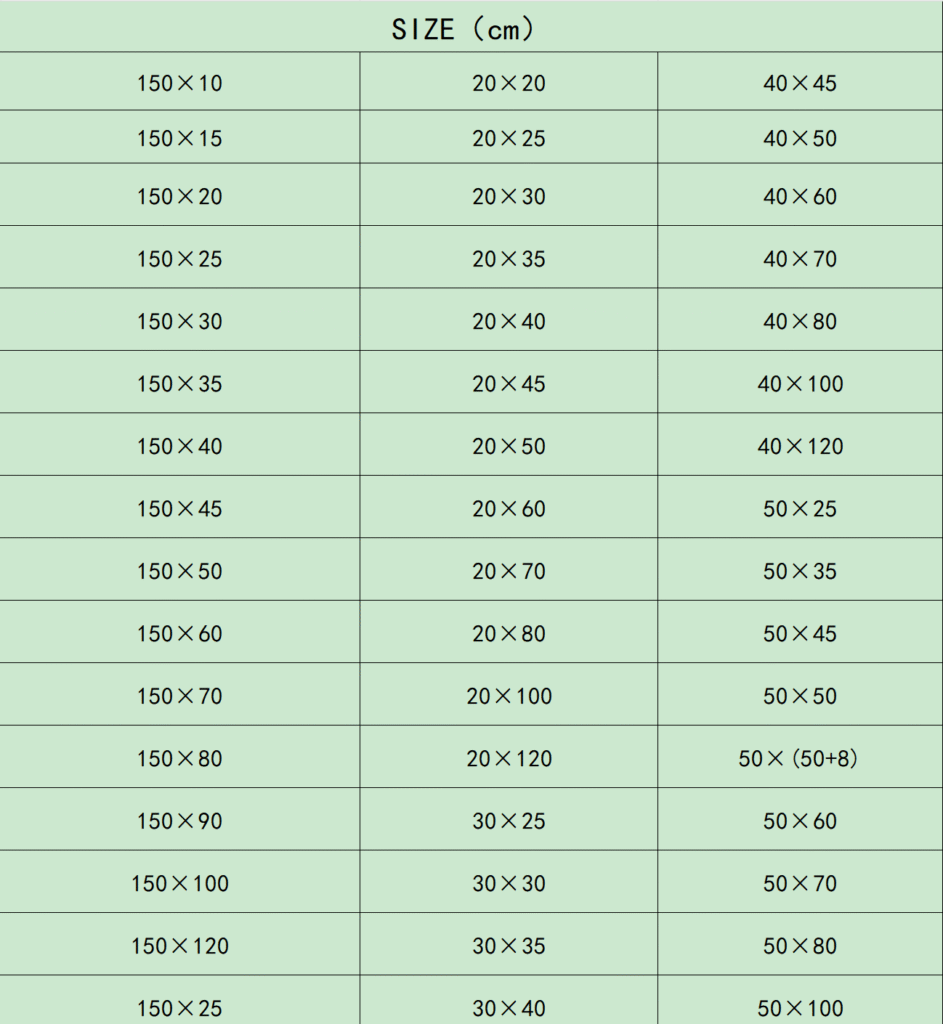

- plastic shuttering size and price

We will offer you the most favorable price. You can click the form below to leave your information, and our technical staff will contact you immediately to provide you with the most suitable formwork system.

- Project Requirements

You need to pick formwork that fits your project. The size and shape of your build matter a lot. Look at your project’s size and shape first. Timber or plastic is good for small jobs. For big or repeat builds, steel or aluminum saves time. If you need strong panels for tall buildings, climbing formwork works well.

Tip: Always choose formwork that fits your project’s size and shape. This helps you get the best concrete formwork for your job.